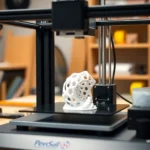

In a world where innovation meets imagination, 3D printing stands as the superhero of manufacturing. But before diving headfirst into this exciting realm, one must navigate the often murky waters of costs. It’s not just about the flashy gadgets or the ability to print your own action figures—understanding the financial implications can make or break your 3D printing dreams.

Overview of 3D Printing Cost Analysis

Understanding 3D printing costs involves recognizing multiple factors influencing overall expenses. Material costs represent a primary expense, as different filament types vary in price, with prices ranging from $20 to $100 per kilogram. Equipment costs follow closely, depending on printer type and brand, typically falling between $200 for entry-level printers to $10,000 for industrial-grade machines.

Operational costs also play a vital role. Electricity usage contributes to the overall expenses, particularly in high-volume printing scenarios. Maintenance costs cannot be overlooked; routine upkeep of the printer ensures continued performance and may require budgeting up to $500 annually for parts and service, depending on usage frequency.

Labor costs can affect the final analysis as well, especially in commercial settings. Skilled operators often demand higher wages, which can add several dollars per hour to the total cost. Lay out these expenses when planning a project for a clearer financial outlook.

Project complexity introduces additional costs. More intricate designs may require expert consultations or specialized tools, increasing expenses further. Designers should factor in design time and software licensing fees, which can run from a few hundred to several thousand dollars.

Ultimately, conducting a thorough cost analysis reveals challenges and opportunities. This financial awareness empowers makers to make informed decisions, ensuring each 3D printing endeavor remains sustainable and viable. Tracking all associated costs provides clarity and helps in adjusting strategies where necessary. Understanding the financial landscape fosters smarter investments and long-term success in 3D printing.

Factors Influencing 3D Printing Costs

Understanding the various factors that influence 3D printing costs is essential for effective financial planning and decision-making. Each element contributes significantly to the overall expense.

Material Costs

Material costs constitute a primary component of 3D printing expenses. Filament prices typically range from $20 to $100 per kilogram, varying based on the material type and quality. For instance, standard PLA filament tends to be more affordable, while specialty materials like nylon or carbon fiber command higher prices. Users must consider both the quantity required for each project and the properties of the chosen materials, as these factors influence not only cost but also the final part’s strength and functionality.

Equipment Costs

Equipment costs present another major factor affecting 3D printing budgets. Entry-level printers start around $200, while industrial-grade machines can reach up to $10,000. The chosen printer directly impacts production capabilities and speed, affecting return on investment. Additionally, various accessories like heated beds, upgraded nozzles, and enclosures could further increase initial costs. Understanding the specific needs of a project helps in selecting the right equipment, balancing performance and budget effectively.

Labor Costs

Labor costs can significantly impact 3D printing projects, especially in commercial applications. Skilled operators often command higher wages, and their expertise proves essential for efficient production. In some scenarios, project complexity may require additional design support or project management, further raising labor expenses. Assessing the required skill level and estimating the time needed for each task contributes to accurate financial planning. Recognizing these labor demands ensures that projects remain within budget while maintaining quality.

Cost Comparison by Printing Technology

Different 3D printing technologies exhibit varied costs associated with materials and equipment. Understanding these distinctions aids in making informed financial decisions.

FDM Technology

Fused Deposition Modeling (FDM) stands out as one of the most affordable 3D printing methods. Filament prices typically range from $20 to $100 per kilogram, depending on the material quality. Entry-level 3D printers for FDM technology cost around $200, whereas high-end options can reach $2,500. Operational expenses remain relatively low, often less than $100 annually for maintenance and energy. Labor costs are minimal for simple projects but can increase with complexity if skilled operators are necessary.

SLA Technology

Stereolithography (SLA) presents higher initial costs compared to FDM. A quality SLA printer can range from $1,500 to $5,000, driven by its precision and material compatibility. Resin prices vary from $50 to $150 per kilogram, influencing overall project expenses. Annual maintenance and operational costs can amount to around $300, as resin handling requires careful attention. Labor expenses tend to be higher for SLA due to the need for design expertise and post-processing.

SLS Technology

Selective Laser Sintering (SLS) demands significant investment in both equipment and materials. Industrial-grade SLS printers start at $10,000, often soaring higher based on complexity and features. The cost of powder materials also impacts budgets, with prices ranging from $60 to $200 per kilogram. While operational costs for SLS can be around $500 annually, they provide high efficiency for large production runs. Skilled labor costs increase due to expertise required for machine operation and post-processing tasks.

Financial Benefits of 3D Printing

Cost savings represent a significant financial benefit associated with 3D printing. Manufacturers experience lower material waste compared to traditional methods, where excess materials often end up discarded.

Speed contributes to cost efficiency in production. Rapid prototyping allows companies to bring products to market faster, eliminating lengthy design iterations and reducing labor costs.

Customizability enhances value for businesses. Creating tailored products becomes possible without extensive retooling, leading to a broader range of offerings and improved customer satisfaction.

Equipment expense varies widely, influencing long-term investment strategies. Entry-level printers start around $200, making them accessible for small businesses. In contrast, industrial-grade machines range from $10,000 or more but offer higher production volumes and compatibility with diverse materials, which ultimately raises return on investment.

Operational efficiency improves with hobbyist and professional 3D printing. Companies can shift to in-house production, reducing reliance on external suppliers and minimizing logistics costs.

Long-term savings accrue from reduced labor expenses. Companies adopting 3D printing often require fewer skilled workers to operate the machines compared to complex traditional manufacturing processes.

Enhanced innovation capabilities present another financial advantage. 3D printing promotes experimentation and iteration at a lower cost, allowing businesses to test ideas without significant upfront investment.

Local production reduces transportation costs. By manufacturing closer to the end user, companies can cut shipping expenses and meet customer demands more efficiently.

The financial benefits of 3D printing span from reduced material usage to faster production timelines, providing several avenues for cost reduction and revenue enhancement.

Challenges in 3D Printing Cost Analysis

3D printing presents multifaceted challenges in cost analysis that can hinder effective budgeting. Fluctuating material prices complicate expense calculations, as filament costs can vary from $20 to $100 per kilogram based on quality and type. Equipment costs also pose a challenge; entry-level printers cost around $200, but industrial-grade machines can soar to $10,000, presenting a steep upfront financial commitment.

Operational costs require consideration as well. Electricity consumption and maintenance expenses can add significant overhead, with annual maintenance potentially reaching up to $500, depending on the printer’s complexity. Labor costs further impact the financial landscape, especially in commercial use, where skilled operators command premium wages. Factors such as project complexity may also necessitate hiring additional design support, amplifying overall expenditures.

Different 3D printing technologies create distinct cost frameworks that complicate comparison. Fused Deposition Modeling (FDM) remains the most affordable, with reasonable filament prices and low initial equipment investment. In contrast, Stereolithography (SLA) bears a higher price tag, with printers averaging between $1,500 and $5,000 and resins costing between $50 and $150 per kilogram. Selective Laser Sintering (SLS) demands significant financial resources for both equipment and materials, with initial investments exceeding $10,000 and powder costs ranging from $60 to $200 per kilogram.

Understanding these variances is crucial for businesses aiming to optimize their 3D printing projects. Without a clear grasp of these challenges, achieving sustainable finances becomes difficult, leading to potential pitfalls in budget management. This detailed analysis reveals the importance of comprehensively evaluating all cost-related aspects to ensure successful 3D printing endeavors.

Conclusion

Understanding the costs associated with 3D printing is vital for anyone looking to harness its potential. By analyzing material expenses equipment investments and operational costs individuals and businesses can make informed decisions that align with their financial goals.

The benefits of 3D printing extend beyond just innovative design. With careful planning and a keen awareness of the financial landscape makers can optimize their projects and achieve sustainable success. Embracing 3D printing not only fosters creativity but also offers significant cost savings and efficiencies that can lead to long-term growth.