In a world where ideas can turn into tangible objects faster than you can say “abracadabra,” 3D printing is the magician every prototyper dreams of. Gone are the days of waiting weeks for a prototype to materialize. With a 3D printer, it’s like having a mini factory right in your garage, ready to whip up your wildest designs at the push of a button.

Imagine transforming your brilliant concepts into real-life models without the headache of traditional manufacturing. Whether it’s a quirky gadget or a sleek product design, 3D printing makes it all possible—and it’s way more fun than assembling IKEA furniture! Dive into the world of 3D printing for prototyping and discover how this technology can elevate your innovation game, save time, and maybe even impress your friends with your newfound wizardry.

Table of Contents

ToggleOverview of 3D Printing for Prototyping

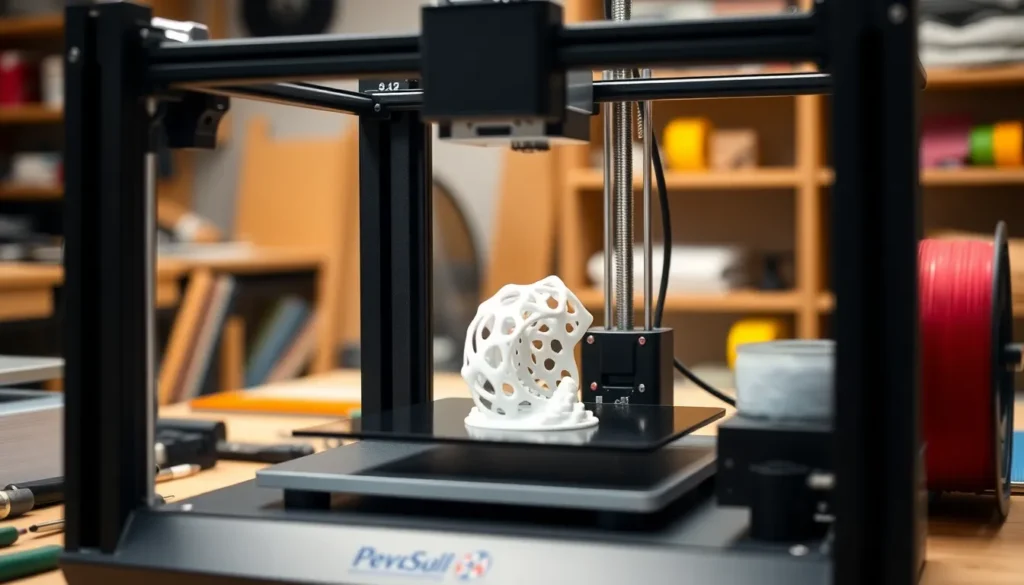

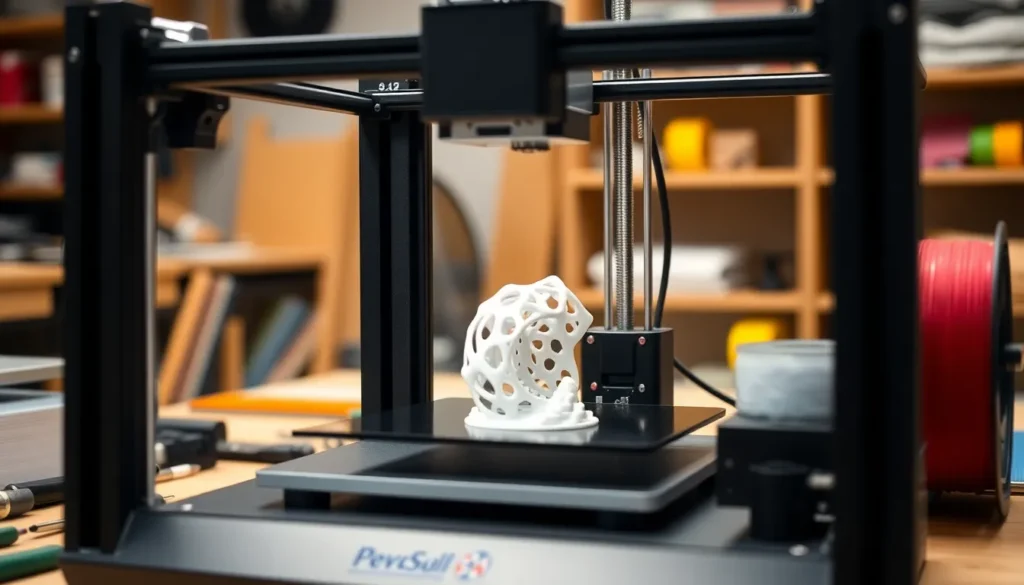

3D printing revolutionizes the prototyping process with its speed and efficiency. This technology allows creators to quickly produce physical models from digital designs.

Definition of 3D Printing

3D printing refers to the additive manufacturing technique that builds objects layer by layer. It uses various materials, such as plastics, metals, and ceramics, to create prototypes. With computer-aided design (CAD) software, users can develop intricate structures. Many industries utilize this method for its ability to produce complex geometries that traditional methods cannot achieve. The process includes multiple technologies, including stereolithography and fused deposition modeling.

Importance in Prototyping

3D printing plays a crucial role in modern prototyping. It significantly reduces lead times, allowing designers to test concepts rapidly. With this technology, stakeholders can evaluate designs and make necessary adjustments without extensive delays. Cost efficiency also improves, as producing prototypes becomes more affordable. Rapid iteration accelerates product development cycles, enabling quicker market entry. Many teams report enhanced collaboration due to shared physical models that facilitate discussion.

Types of 3D Printing Technologies

3D printing employs several technologies, each serving unique purposes in prototyping. Understanding these methods helps users select the best option for their projects.

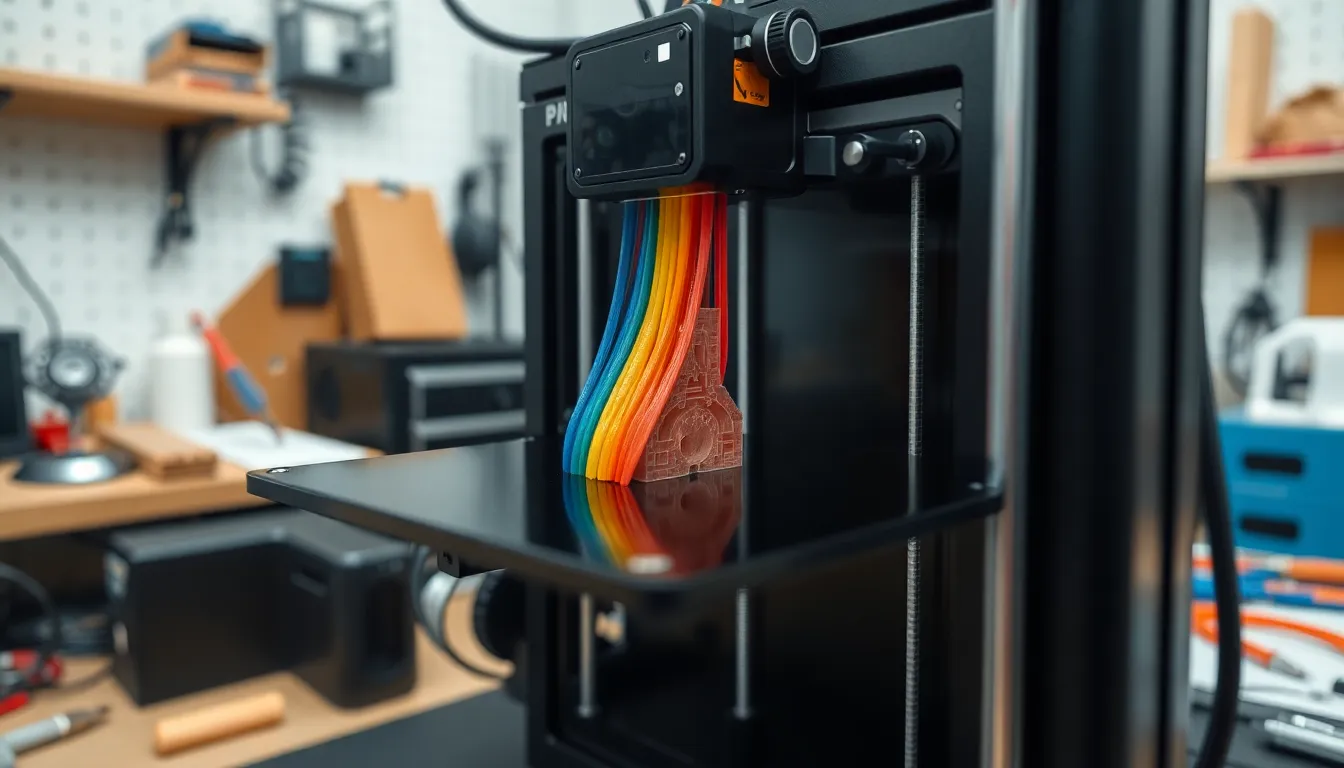

Fused Deposition Modeling (FDM)

Fused Deposition Modeling, or FDM, utilizes thermoplastic materials. It works by melting filament and extruding it layer by layer to form an object. This method stands out for its cost-effectiveness and ease of use, making it popular among hobbyists and professionals alike. Common applications include functional prototypes and concept models. Various materials like ABS and PLA contribute to its versatility, while a wide range of compatible printers adds convenience.

Stereolithography (SLA)

Stereolithography, known as SLA, employs a UV light source to cure liquid resin. The light solidifies the resin layer by layer, creating detailed and high-resolution parts. This technology excels in producing intricate designs and smooth surface finishes. Industries often use SLA for prototypes that require precision, such as dental and jewelry applications. A variety of resin types further enhances its capabilities, offering characteristics like flexibility or rigidity.

Selective Laser Sintering (SLS)

Selective Laser Sintering, abbreviated to SLS, relies on a laser to fuse powdered material into solid objects. This method supports a wide array of materials, including plastics and metals. SLS boasts strength and durability, making it ideal for functional prototypes and end-use parts. The self-supporting nature of the powder allows for complex geometries without additional supports. Industries like aerospace and automotive frequently turn to SLS for high-performance prototypes.

Advantages of 3D Printing for Prototyping

3D printing offers several significant advantages for prototyping, making it a preferred choice among designers and engineers.

Cost-Effectiveness

Cost-effectiveness defines much of 3D printing’s appeal in prototyping. Traditional manufacturing often requires expensive molds and tooling, increasing overall expenses. In contrast, 3D printing eliminates many of these initial costs, allowing for cheaper production of prototypes. Material waste significantly lowers, which contributes to reduced costs. Even small production runs become financially viable, offering substantial savings for businesses and startups alike. This accessibility empowers a wider range of innovators to bring their ideas to life without hefty financial burdens.

Speed and Efficiency

Speed and efficiency are key advantages that 3D printing brings to prototyping processes. Designers can create prototypes within hours, not weeks, enabling rapid product development. The ability to iterate quickly allows for timely adjustments based on feedback. This fast turnaround accelerates the design cycle, keeping projects on schedule. In industries where timing is crucial, such as technology and consumer products, the swift pace of 3D printing can prove critical to maintaining competitive advantage.

Design Flexibility

Design flexibility showcases another essential benefit of 3D printing in prototyping. Complex geometries that traditional manufacturing methods struggle to produce become easily achievable with this technology. Designers can experiment with intricate models without the limitations of conventional processes. Furthermore, modifications can happen rapidly, allowing for quick iterations of designs. This flexibility fosters innovation, as teams are more willing to explore unconventional ideas, ultimately leading to better and more functional products.

Applications of 3D Printing in Prototyping

3D printing plays a vital role across various industries, showcasing its versatility in prototyping. Here are a few key applications:

Automotive Industry

In the automotive sector, 3D printing allows quick development of intricate components, reducing lead times significantly. Designers create functional prototypes of parts such as brackets and housings within days, rather than weeks. This method enhances collaboration, as engineering teams can visualize and test various designs rapidly. Manufacturers rely on additive technology for producing lightweight components, which ultimately leads to improved fuel efficiency.

Healthcare Sector

The healthcare sector benefits from 3D printing by producing custom medical implants and prosthetics tailored to individual patient needs. Surgeons use prototypes to plan complex procedures, improving surgical outcomes. Additionally, dental practices adopt this technology to create precise dental models within hours, streamlining the patient experience. This innovative approach not only enhances patient care but also fosters collaboration among healthcare professionals.

Consumer Products

In the consumer products realm, 3D printing enables rapid prototyping for an array of items, from electronics to household goods. Inventors can test multiple iterations of a product quickly, allowing for timely market entry. Companies benefit from reduced material waste and cost savings during the prototyping phase. This capacity for rapid innovation encourages businesses to experiment with complex designs that would be challenging using traditional methods.

Challenges and Limitations

3D printing benefits prototyping but presents several challenges and limitations. Addressing these constraints is crucial for optimizing this technology in design and manufacturing.

Material Constraints

Materials available for 3D printing often limit functionality. Designers must consider the specific properties of plastics, metals, and ceramics when selecting materials for prototyping. Each type of material has different strengths, weaknesses, and applications. For instance, some plastics may not withstand high temperatures, while metals may require specialized printers. Identifying the right material for a particular use case can significantly impact the performance and durability of prototypes.

Surface Finish and Detail

Surface finish and level of detail present significant challenges in 3D printing. Many printed prototypes exhibit rough textures or visible layer lines, particularly with Fused Deposition Modeling (FDM) technology. Achieving a smooth finish often requires additional post-processing steps that increase time and costs. Additionally, intricate designs may not translate well into printed forms, leading to loss of significant detail. Ensuring adequate resolution becomes critical when precision is a priority in prototyping.

Scalability Issues

Scalability poses a challenge for production-oriented prototypes. While 3D printing excels in rapid iteration, it lacks efficiency for large-scale manufacturing. The time required for each individual print can hinder mass production efforts. As output needs increase, using traditional manufacturing methods becomes more attractive due to faster production rates. Balancing the benefits of 3D printing with scaling requirements often means combining techniques to meet diverse project demands effectively.

3D printing has revolutionized the prototyping landscape by offering unprecedented speed and flexibility. Its ability to produce high-quality prototypes quickly not only enhances creativity but also accelerates the product development cycle. As industries continue to embrace this technology, the advantages of cost savings and design freedom become increasingly apparent.

While challenges such as material limitations and surface finish remain, the benefits of rapid iteration and collaboration far outweigh these obstacles. By integrating 3D printing into their workflows, designers and engineers can unlock new possibilities, ultimately leading to innovative solutions and improved products. Embracing this transformative technology is essential for anyone looking to stay ahead in today’s competitive market.