Ever wondered how long it takes to turn a digital dream into a tangible reality? With 3D printing, the answer might surprise you. This revolutionary technology can transform your wildest ideas into physical objects, but just like waiting for your favorite pizza delivery, the time it takes can vary.

Factors Affecting 3D Printing Time

3D printing time varies based on several factors. Understanding these elements helps clarify how long a project may take.

Print Size and Complexity

Print size significantly impacts the duration of a project. Larger objects require more material and take longer to complete. Complexity adds another layer, as intricate designs often slow down the process. For instance, detailed models with numerous features consume additional time due to increased printing demands. Simple shapes and small items print quickly, making quick prototyping efficient. Custom sizes and shapes also affect overall print time, necessitating adjustments in printer settings.

Layer Height and Resolution

Layer height determines the level of detail in 3D prints. Thinner layers yield finer results but increase printing time. For example, a layer height of 0.1 mm provides excellent detail but takes longer than a height of 0.3 mm. Higher resolution prints look smoother and more refined, while lower resolution prints complete faster but may appear rough. Balancing quality with speed becomes essential, especially when time constraints exist. Higher resolutions often lead to longer print sessions, while standard resolutions provide faster turnaround.

Types of 3D Printing Technologies

3D printing technologies encompass various methods, each affecting production time differently. Here are two prominent techniques.

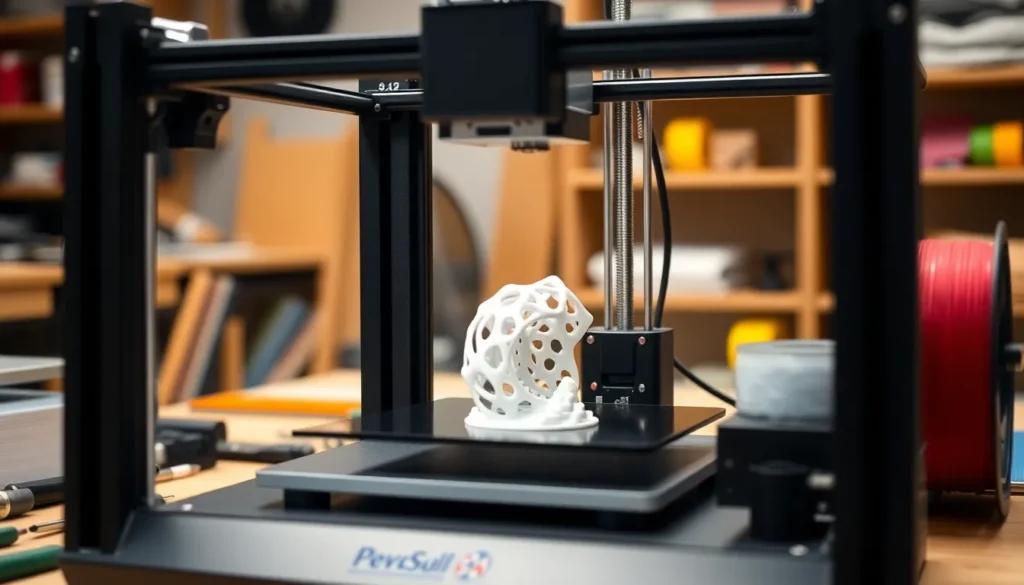

FDM Printing

Fused Deposition Modeling (FDM) represents one of the most common 3D printing methods. This technology uses thermoplastic filaments, melting material layer by layer to create objects. Print time for FDM depends on factors such as model size, layer height, and print speed. Larger models increase duration significantly, while finer layer heights deliver superior detail at the expense of time. Enthusiasts often favor FDM for its affordability and ease of use, allowing for quick prototyping. Typical print times range from a couple of hours for smaller objects to several days for more complex designs.

SLA Printing

Stereolithography (SLA) provides an alternative approach, focusing on resin curing. This method uses ultraviolet light to solidify liquid resin layer by layer. SLA offers high precision and intricate detail, making it ideal for detailed models. While SLA prints often finish faster than FDM for small objects, larger prints require additional time due to longer exposure cycles. Users appreciate SLA’s ability to produce smooth surfaces and intricate geometries. Average printing durations can range from under an hour for smaller prints to multiple hours for large models, affected heavily by layer thickness and model complexity.

Typical Print Times for Common Projects

Print times for 3D projects vary based on size and complexity. Understanding these timeframes helps set expectations for production.

Small Prints

Small prints often take between one to three hours to complete. These projects, typically under 50 cubic centimeters, require less material and shorter build times. An example includes small figurines or basic keychains. The simplicity of the design plays a crucial role in the duration, allowing for efficient printing. Since less infill and fewer supports are needed, overall time reduces significantly.

Medium Prints

Medium prints generally range from three to ten hours in duration. Objects measuring between 50 and 300 cubic centimeters fall into this category. Items like custom phone cases or small mechanical parts display noticeable complexity, doubling the time compared to smaller prints. Layer height and print settings also impact the overall timing. Using thicker layers can speed up the process, while higher resolutions prioritize detail.

Large Prints

Large prints can take ten hours to several days, depending on design intricacy and dimensions. Items exceeding 300 cubic centimeters often necessitate significant build time. 3D printing components like prosthetics or larger prototypes exemplify this category. The combination of complexity, size, and necessary supports makes each project unique. Smaller parts may print quickly, yet full assemblies require extensive patience.

Optimizing 3D Printing Time

Optimizing the time needed for 3D printing involves tweaking several factors. Adjusting print settings provides one of the most effective means to save time while maintaining quality.

Print Settings Adjustments

Modifying layer height significantly influences print duration. Thicker layers reduce printing time but may sacrifice detail. Increasing print speed enhances productivity but can lead to compromised quality if not monitored closely. The nozzle temperature affects the flow of filament. Higher temperatures can facilitate faster extrusion rates. Balancing these settings is crucial for achieving optimal results without unnecessary delays.

Pre-Print Preparation

Proper pre-print preparation minimizes potential time-wasting issues. Ensuring the build surface is clean promotes better adhesion and reduces the likelihood of failed prints. Slicing software should be used effectively to identify the most efficient print path. Checking for errors in the 3D model can prevent complications during the printing phase. Moreover, organizing the workspace ensures quick access to materials, which can streamline the setup process. Taking these steps proactively contributes to a smoother printing experience.

3D printing offers a fascinating glimpse into the future of manufacturing. Understanding the time it takes to print different objects is essential for anyone looking to leverage this technology. By considering factors like print size complexity and the chosen method, individuals can better manage their expectations and project timelines.

Optimizing print settings and preparing effectively can lead to significant time savings without compromising quality. As 3D printing continues to evolve it will undoubtedly become even more efficient. Embracing these insights can help users navigate the exciting world of 3D printing with confidence and precision.