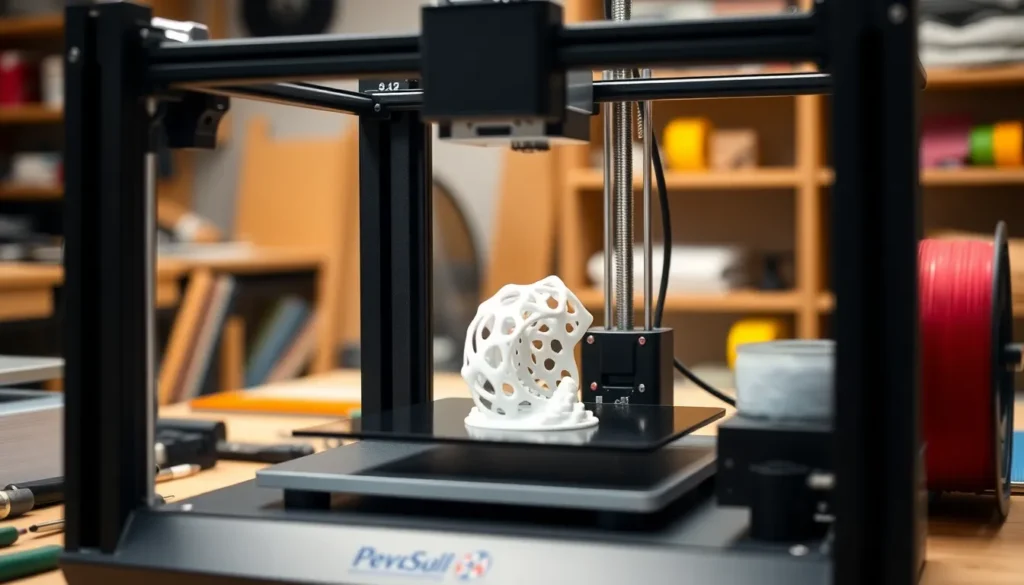

3D printing has transformed from a futuristic fantasy into a reality that’s reshaping industries and sparking creativity. But before diving headfirst into this world of layer-by-layer magic, one burning question lingers: how much does it really cost? Spoiler alert: it’s not as simple as checking the price tag on a fancy coffee.

Table of Contents

ToggleOverview of 3D Printing Costs

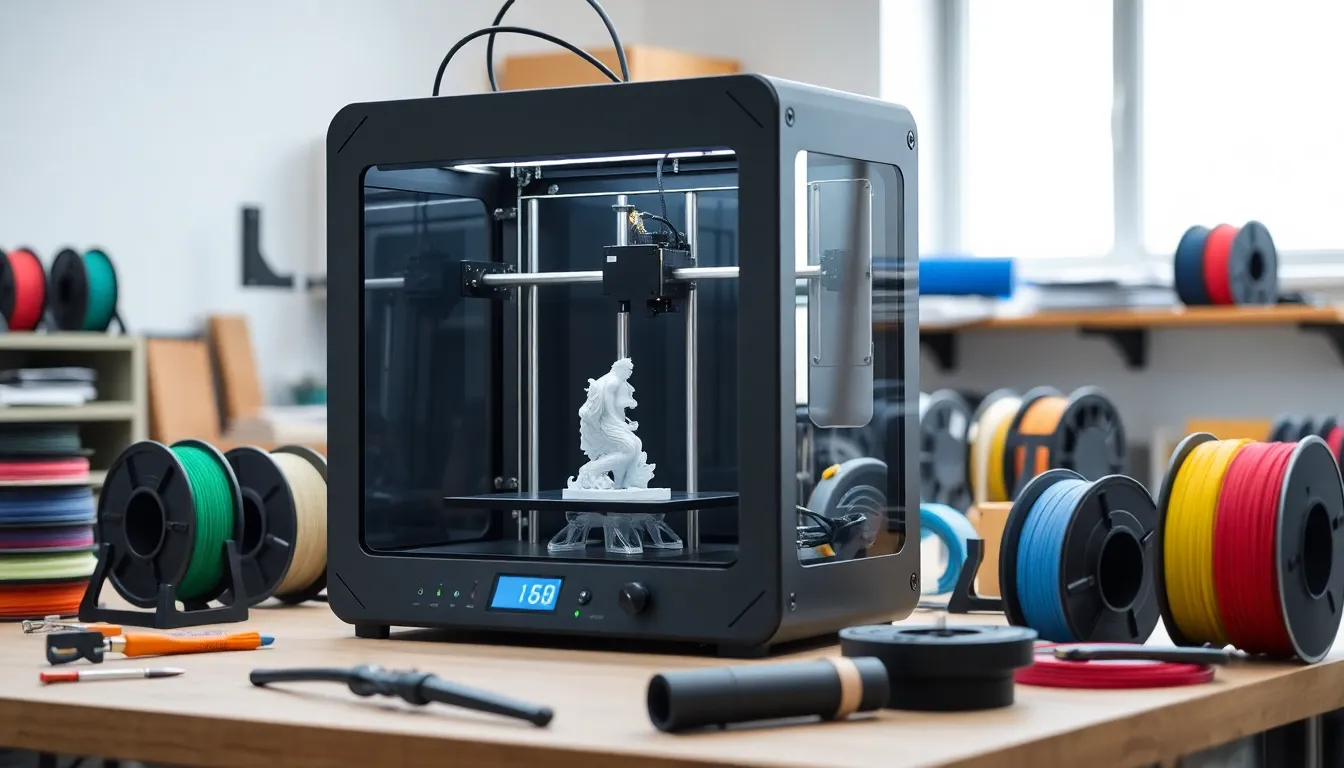

3D printing costs encompass several factors, including printer types, material expenses, and operational overhead. Three main categories influence these costs: initial investment, ongoing production, and post-processing.

Initial investment includes the purchase of the 3D printer and associated software. Basic desktop models range from $200 to $2,000. Industrial-grade printers can start at $10,000 and exceed $100,000, depending on the technology and specifications required. The increasing affordability of entry-level machines has spurred wider adoption among hobbyists and small businesses.

Material expenses form another significant portion of 3D printing costs. Filaments, resin, and powders vary in price across different materials. For example, common filaments like PLA and ABS cost around $20 to $50 per kilogram, while specialty materials such as nylon or metal powders can reach $100 per kilogram or more. This variety allows users to select materials based on functionality and budget.

Ongoing production costs also contribute to the overall expense. Factors include maintenance, energy consumption, and labor. A typical 3D print operation might consume approximately $0.50 to $3.00 in electricity per hour, depending on machine efficiency. Maintenance costs vary, with an estimate of $200 to $500 annually for repair and upkeep.

Post-processing steps often add further costs. Processes like sanding, painting, or assembly require additional time and materials. Each stage can increase the project cost, making it essential to account for these factors when evaluating overall expenses.

Understanding 3D printing costs involves more than simply considering material and machine prices. Each factor plays a role, influencing decisions about adoption, scale, and project viability.

Factors Influencing 3D Printing Costs

Understanding the costs of 3D printing involves analyzing various factors. Each component impacts the overall investment necessary for projects.

Material Costs

Material expenses represent a significant portion of 3D printing costs. Common filaments typically range from $20 to $50 per kilogram. Specialty materials, such as nylon or resin, can escalate to $100 per kilogram or more. Selecting the right material affects not only the print quality but also durability and finish. Moreover, using advanced materials introduces additional benefits, ideal for specific applications. Keeping track of material costs is essential for accurate budgeting in any 3D printing project.

Machine Costs

Machine costs vary greatly depending on the printer’s type and capabilities. Basic desktop 3D printers generally range from $200 to $2,000. In contrast, industrial-grade printers start at $10,000 and can exceed $100,000, reflecting advanced features and higher production capabilities. Along with the purchase price, software costs can add to the initial investment. Regular maintenance and potential upgrades should also factor into long-term expenses. Evaluating machine costs thoroughly ensures informed decisions for desired project outcomes.

Labor Costs

Labor expenses contribute to the overall cost structure of 3D printing. Skilled technicians, often necessary for setup and operation, command varying wages based on experience. Training employees on advanced printing techniques incurs further costs, particularly for complex projects. Additionally, post-processing tasks require skilled labor to achieve desired finishes. Evaluating labor requirements assists in forming a complete financial picture. Analyzing these costs helps organizations budget accurately for successful 3D printing initiatives.

Cost Comparisons

Understanding the costs associated with 3D printing involves examining various technologies and their pricing structures, as well as comparing DIY options with professional services.

Different 3D Printing Technologies

Fused Deposition Modeling (FDM) printers remain the most common, with prices for entry-level models averaging $200 to $1,000. Stereolithography (SLA) printers, on the other hand, typically cost between $500 and $5,000 due to their advanced resin-based processes. Selective Laser Sintering (SLS) systems range from $5,000 to over $100,000, given their capabilities for creating complex, high-quality parts. Material costs also differ considerably, with FDM filament priced at $20 to $50 per kilogram, while SLA resin may start at $50, reaching $150 per kilogram. Evaluating these technologies allows for better planning of expenses based on project requirements.

DIY vs. Professional Services

Opting for DIY 3D printing can save money on initial costs, but experienced users still incur expenses related to materials, maintenance, and time. Purchasing an entry-level printer and filament may total around $500 to $2,000, depending on the complexity. Conversely, professional services handle everything from design to final product delivery, typically charging between $50 and $150 per hour, with additional material costs factored in. Choosing between DIY and professional services depends on project complexity, budget, and desired print quality; each route presents specific financial implications.

Budgeting for 3D Printing

Budgeting for 3D printing involves understanding several cost components. Initial investments cover the purchase of a 3D printer and necessary software, affecting overall expenditures. Generic desktop models typically sell for $200 to $2,000. Meanwhile, industrial-grade printers range significantly from $10,000 to over $100,000.

Material expenses also represent a crucial factor in the budget. Standard filaments usually cost between $20 and $50 per kilogram. Specialty materials, however, can escalate much higher, often reaching prices of $100 per kilogram or more. Assessing material choice not only impacts costs but also influences print quality and durability.

Regular operational costs factor into the overall budget as well. Maintenance expenses, energy consumption, and labor costs contribute to ongoing production expenses, which can vary widely based on printer type and usage frequency. Skilled technicians might be required for setup and post-processing tasks, generating additional costs.

Post-processing techniques, which can include sanding and painting, add another layer to the expenses. Depending on the complexity of the project, these expenses can accumulate quickly, impacting the total project budget significantly.

Various 3D printing technologies also present different budgeting scenarios. For instance, Fused Deposition Modeling (FDM) represents a cost-effective choice, with entry-level models averaging between $200 and $1,000. Stereolithography (SLA) printers generally range from $500 to $5,000, while Selective Laser Sintering (SLS) systems can exceed $100,000.

Understanding these cost components helps individuals and organizations create accurate budgets for their 3D printing projects. Decisions surrounding 3D printing methods depend heavily on project complexity, budget constraints, and desired print quality.

Navigating the costs of 3D printing requires a nuanced understanding of various factors. From the initial investment in equipment to ongoing material and operational expenses, each component plays a vital role in the overall budget.

Organizations and individuals alike must weigh their options carefully. Whether opting for DIY solutions or professional services, the right choice hinges on project needs and financial considerations. By grasping the intricacies of 3D printing costs, they can make informed decisions that align with their goals and resources. Ultimately, a well-planned budget can unlock the full potential of this innovative technology.