In the ever-evolving world of 3D printing, PETG has burst onto the scene like a superhero in spandex. This thermoplastic is making waves for its perfect blend of strength and flexibility, leaving other materials scratching their heads in envy. Whether you’re a hobbyist crafting intricate designs or a professional tackling serious projects, PETG is the sidekick you never knew you needed.

Table of Contents

ToggleOverview of PETG 3D Printing

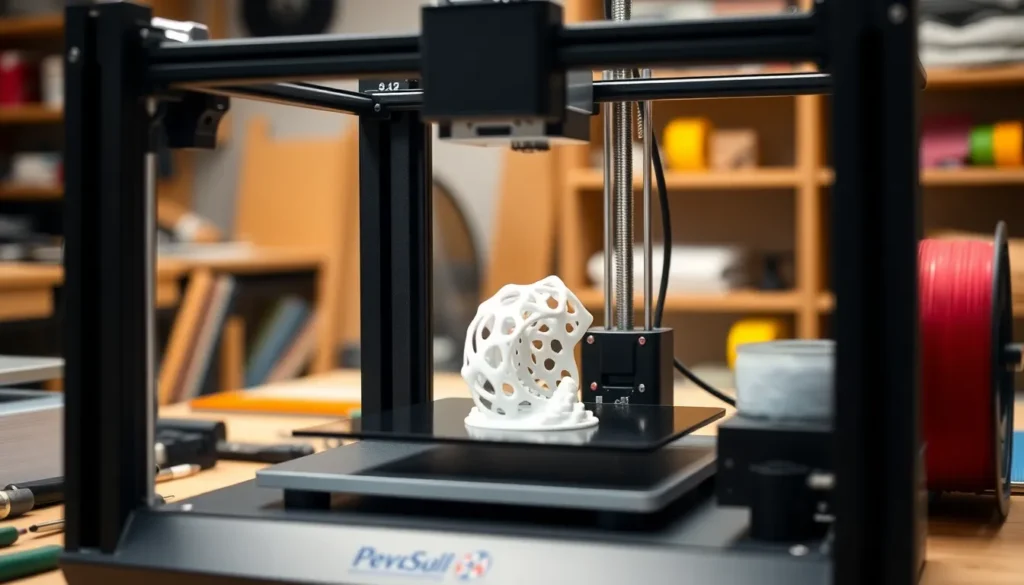

PETG (Polyethylene Terephthalate Glycol) is a widely used thermoplastic in 3D printing, known for its durability and ease of use. Many enthusiasts prefer it for its excellent layer adhesion, which leads to stronger prints. Strength and flexibility make PETG suitable for a variety of applications, including functional prototypes and end-use parts.

Temperature resistance defines PETG, as it maintains shape and integrity under heat. This characteristic becomes critical for parts exposed to varying temperatures during use. Printing temperature typically ranges from 230°C to 250°C, making it a versatile material compatible with most FDM printers.

Post-processing options play a significant role in finishing PETG prints. Common techniques include sanding and vapor smoothing, which enhance appearance and provide a polished finish. This material also resists impact and chemicals, making it ideal for industrial applications and outdoor use.

Safety aspects matter with PETG as it emits fewer odors compared to other materials during the printing process. This feature makes it suitable for home or office environments. Filament colors offer a variety, catering to both aesthetic and functional needs, ensuring users find the right options for their projects.

Overall, PETG stands out in the 3D printing community for its remarkable properties and versatility. With ongoing advancements in printing technology, its popularity is likely to increase among both hobbyists and professionals alike.

Benefits of PETG 3D Printing

PETG offers numerous advantages in 3D printing, making it a favored choice among enthusiasts and professionals. Its unique properties contribute to exceptional applications in various fields.

Durability and Strength

Durability plays a critical role in PETG’s appeal. This material withstands significant wear and tear, ensuring longevity in printed objects. Prints exhibit impressive layer adhesion, which enhances overall strength. Unlike some other filaments, PETG resists cracking or breaking under stress, making it ideal for functional prototypes. Additionally, its heat resistance allows prints to maintain structural integrity even at elevated temperatures. Industries such as automotive and aerospace frequently utilize PETG due to these robust characteristics.

Flexibility and Impact Resistance

Flexibility is another key benefit of PETG. The material’s ability to bend without breaking makes it suitable for a wide range of applications. Impact resistance is substantial, allowing PETG prints to absorb shocks without suffering damage. This property benefits those creating parts that experience frequent handling or movement. Designers often choose PETG for items such as protective cases and robust tools. With its balanced combination of flexibility and durability, PETG meets the demands of various projects, ranging from casual hobbies to industrial components.

Applications of PETG 3D Printing

PETG’s versatility allows it to serve various applications across multiple industries, showcasing its strength and adaptability in 3D printing.

Prototyping and Product Development

Prototyping leverages PETG’s strength and flexibility. Designers and engineers create functional prototypes that undergo rigorous testing without compromising quality. This material withstands stress, making it ideal for evaluating product designs. Additionally, product developers appreciate PETG for its excellent layer adhesion, resulting in durable prototypes. The ease of printing at temperatures ranging from 230°C to 250°C allows teams to iterate quickly. For rapid prototyping, PETG offers the reliability many professionals seek, ensuring that prototypes accurately reflect the final product’s performance.

Medical and Dental Uses

Medical and dental fields increasingly rely on PETG for custom applications. Its biocompatibility and strength make it suitable for producing medical devices and dental models. Professionals create accurate anatomical models for surgical planning, benefiting from PETG’s precision. Furthermore, the material’s resistance to chemicals ensures durability and safety in medical environments. Dental practitioners use it to fabricate clear aligners and dental prosthetics, providing comfortable and effective solutions for patients. As healthcare advances, PETG continues to play a crucial role in innovative medical applications, proving its value in sensitive environments.

Comparison with Other Filaments

Understanding how PETG compares to other filaments enhances the choice for specific applications.

PETG vs. PLA

PETG and PLA serve different needs in 3D printing. PLA, derived from renewable resources, is biodegradable, making it an eco-friendly option. It’s simpler to print with, producing minimal warping. However, PETG offers enhanced durability and impact resistance, which appeals to users needing functional parts. While PLA is prone to brittleness under stress, PETG maintains its structure and flexibility. Additionally, PETG works well in higher temperatures, maintaining shape better than PLA. For outdoor use or mechanical parts, PETG’s UV resistance makes it more reliable than PLA.

PETG vs. ABS

PETG and ABS each offer distinct advantages. ABS excels in strength and toughness, often used for industrial applications. However, it has a higher tendency to warp during printing and emits odors that can be unpleasant. In contrast, PETG provides excellent layer adhesion and lower warping, creating a more user-friendly experience. While ABS is known for its post-processing options, like chemical smoothing, PETG’s smooth finish requires less work. Both materials withstand elevated temperatures, but PETG’s impact resistance and chemical durability often make it the preferred choice for versatile projects.

Best Practices for PETG 3D Printing

PETG 3D printing requires attention to detail for optimal results. Users should focus on specific settings to enhance print quality and ensure successful builds.

Recommended Print Settings

Printing temperatures should range from 230°C to 250°C. Layer height settings between 0.1mm and 0.3mm produce effective results. Printing speed should ideally be set between 40mm/s and 60mm/s to balance accuracy and speed. Users might find that increasing bed temperature from 70°C to 80°C helps prevent warping. The use of a cooling fan at around 30% to 50% assists in achieving smoother surfaces and better detail.

Post-Processing Techniques

Sanding is an effective method to enhance the surface finish of PETG prints. Users can begin with coarse grit sandpaper and progress to finer grits for a polished look. Vapor smoothing stands out as a technique to improve aesthetics by using acetone vapors. Applying a clear coat offers an additional layer of protection, enhancing durability and appearance. Customization options include painting PETG with acrylic paints for various aesthetic finishes, adding both functionality and beauty to prints.

PETG 3D printing stands out as a reliable choice for both hobbyists and professionals. Its remarkable strength and flexibility make it ideal for a wide range of applications from functional prototypes to intricate designs. The material’s durability and excellent layer adhesion ensure that prints maintain their integrity under stress.

With its resistance to impact and chemicals PETG proves invaluable in industrial settings and outdoor use. As 3D printing technology evolves PETG’s versatility is likely to attract even more users. Adopting best practices for printing and post-processing can further enhance the quality of PETG prints. This makes it a top contender in the ever-growing landscape of 3D printing materials.