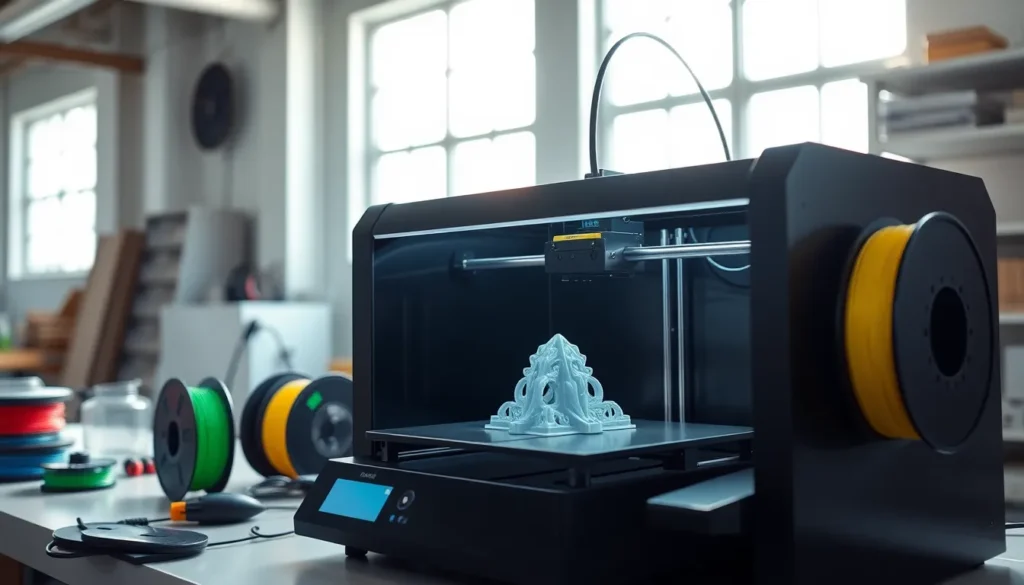

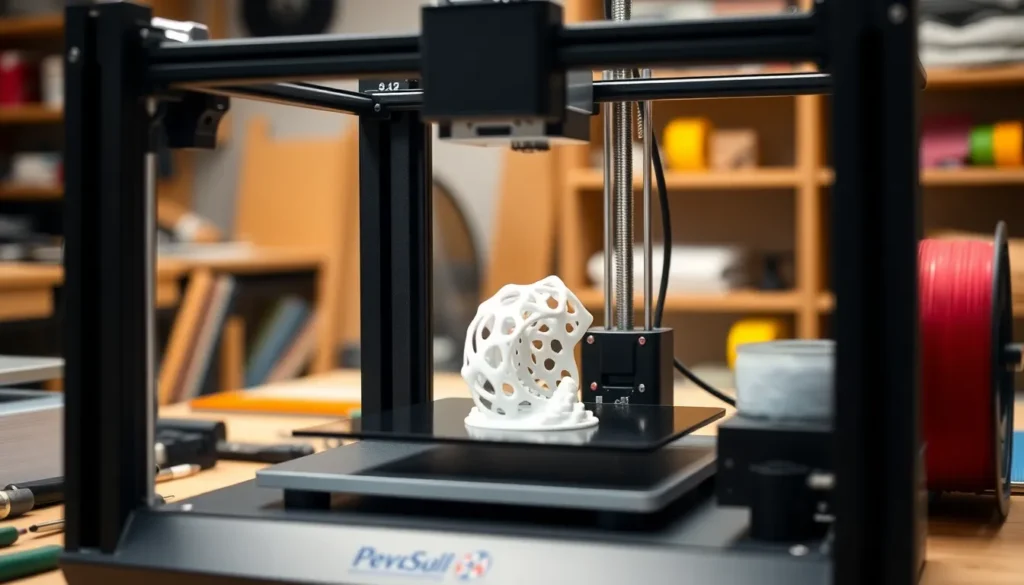

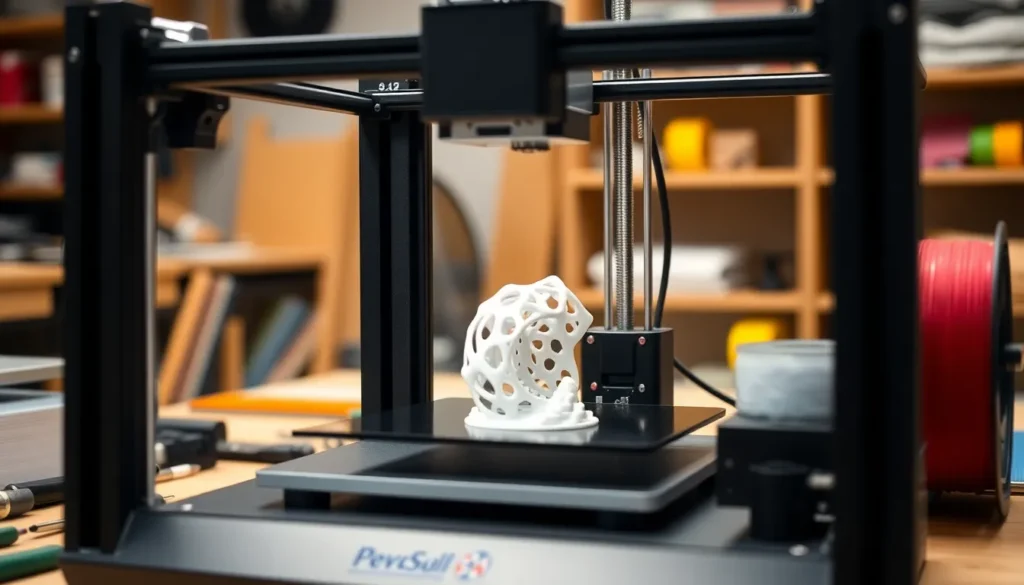

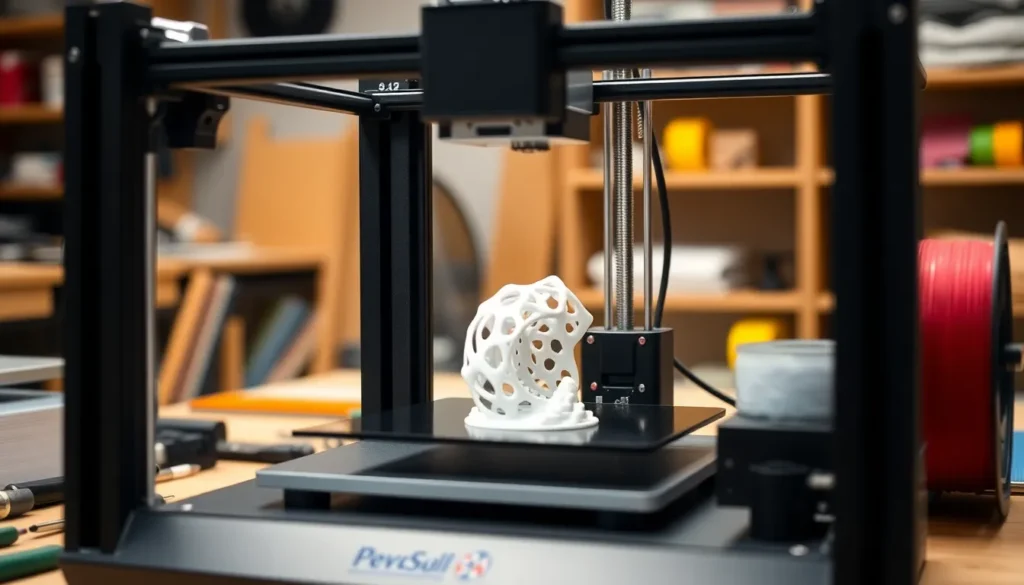

3D printing isn’t just a fad; it’s a revolution that’s reshaping how we create everything from toys to medical devices. As the technology evolves at lightning speed, staying updated is crucial for anyone who wants to keep their edge in this dynamic landscape. Picture this: instead of waiting weeks for a custom part, you can whip it up in your own workshop while sipping coffee. Who wouldn’t want that?

Table of Contents

ToggleOverview of 3D Printer Technology Updates

Recent advancements in 3D printer technology have enhanced not only performance but also accessibility for various industries. New materials, such as metal composites and biocompatible polymers, enable manufacturers to create stronger and more versatile products. Innovations in print speed reflect improvements in hardware, with some printers achieving speeds exceeding 500 mm/s, significantly reducing production times.

Multiple 3D printing methods now exist beyond traditional Fused Deposition Modeling (FDM). Selective Laser Sintering (SLS) and Stereolithography (SLA) present options for industries seeking high precision and reliability. These approaches facilitate complex geometries and fine detail, thereby meeting the increasing demands for customization in manufacturing.

Software upgrades play a crucial role in optimizing 3D printer efficiency. New slicing software features machine learning algorithms that improve print quality and reduce material waste. Users witness improved ease in design modification, allowing rapid iteration during the prototyping phase.

Maintenance has become simpler due to modular designs in modern printers, which allow quick part replacement. Users benefit from increased uptime, thus enhancing productivity. Remote monitoring capabilities empower operators to track printer performance and receive alerts, streamlining the overall printing process.

Collaboration between manufacturers is driving innovation in 3D printer technology. Partnerships aim to share research and development findings, leading to rapid enhancements in capabilities and reducing production costs. As technologies converge, those industries keen on 3D printing will find themselves at the forefront of technical advancements.

Through these updates, 3D printing continues to reshape manufacturing by driving efficiencies and expanding possibilities for custom applications across diverse sectors.

Recent Advancements in 3D Printing Materials

Ongoing advancements in 3D printing materials enhance design flexibility and performance capabilities. Innovations create opportunities for industries seeking specific functionalities and greater efficiency.

New Material Innovations

New materials expand the range of 3D printing applications. Researchers have introduced metal composites, which combine strong metal properties with lightweight features. Additionally, biocompatible polymers meet the needs of the medical sector, supporting safety in patient applications. Thermoplastics, elastomers, and resins have seen improvements that heighten durability and surface finishes. Eco-friendly filaments, made from renewable resources, also address sustainability concerns while maintaining print quality. Such innovations contribute to user preferences and facilitate diverse manufacturing processes.

Pros and Cons of Emerging Materials

Emerging materials present both benefits and challenges. Strength and durability improve with many new composites, allowing for advanced applications in aerospace and automotive industries. The introduction of biocompatible materials fosters growth in medical devices while complying with regulatory standards. However, costs often rise due to materials’ uniqueness, impacting affordability for smaller businesses. Limited availability may hinder rapid adoption and integration. Some materials also require specific printing conditions, raising complexity in the production process. Balancing these factors is crucial for companies aiming to leverage advanced 3D printing technologies effectively.

Software Improvements in 3D Printing

Advancements in software significantly enhance the capabilities of 3D printing systems, allowing for greater precision and efficiency.

Enhanced Design Software Features

Modern design software incorporates intuitive interfaces and advanced tools. Users benefit from parametric modeling, enabling easy adjustments to design specifications. Some applications support collaborative features, allowing teams to work together seamlessly, regardless of location. Integration with simulation tools helps identify potential design flaws before printing, reducing material waste. Features like version control streamline project management, ensuring consistency and smooth progress.

Impact of AI on 3D Printing Software

Artificial intelligence revolutionizes 3D printing software by optimizing various aspects of the printing process. AI algorithms analyze historical print data to predict potential failures, improving print reliability. Through machine learning, software adapts to user preferences, making personalized recommendations for faster prints. Resource management becomes more efficient, minimizing material waste with precise calculations. AI also enhances user experience, automating repetitive tasks and allowing operators to focus on higher-level design decisions.

Industry Applications of 3D Printing

3D printing technology finds extensive applications across several industries, enhancing efficiency and design capabilities.

Medical Sector Innovations

Innovations in the medical sector leverage 3D printing for custom prosthetics and implants. Surgeons use patient-specific models for pre-surgical planning, improving precision and outcomes. Bioprinting enables the creation of tissue structures, opening pathways for organ donation solutions. Researchers continue developing biocompatible materials, ensuring safety for long-term use. Additionally, production speed reduces turnaround times for medical devices, ensuring timely patient care.

Automotive and Aerospace Developments

Automotive and aerospace sectors increasingly adopt 3D printing for lightweight components and complex geometries. Manufacturers utilize this technology for rapid prototyping, allowing them to test designs before mass production. Advanced materials reduce weight, enhancing fuel efficiency and performance. Customization plays a vital role; businesses create tailored parts to fit specific needs. Furthermore, significant cost reductions in production help companies stay competitive in a changing market.

Sustainability in 3D Printing

3D printing technology increasingly embraces sustainability by incorporating eco-friendly practices and reducing material waste. Innovations evolve rapidly, creating ways to minimize environmental impact.

Eco-Friendly Printing Practices

Materials used in 3D printing now include biodegradable filaments and recycled plastics, making the process more environmentally friendly. Biopolymers derived from natural sources offer a reduction in carbon footprint compared to traditional materials. Companies focus on sourcing sustainable raw inputs, fostering a circular economy. Many manufacturers adopt energy-efficient printers, decreasing power consumption during production. Additionally, eco-conscious brands prioritize sustainable packaging solutions, further enhancing overall environmental responsibility.

Reducing Waste with 3D Technologies

3D printing minimizes waste through additive manufacturing principles, layering materials only where needed. Traditional subtractive methods often lead to significant waste, while 3D printing optimizes material usage and design. Software improvements enable precise calculations for required materials, further lowering excess. Companies analyze production processes with AI algorithms, identifying opportunities to cut waste. As the technology continues to advance, more efficient machinery and methods will likely lead to further reductions in waste across industries.

The advancements in 3D printing technology are reshaping industries in remarkable ways. As new materials and faster printing methods emerge, the potential for customization and efficiency grows exponentially. The integration of artificial intelligence and innovative software further enhances the reliability and precision of 3D printing processes.

Sustainability remains a crucial focus as eco-friendly practices gain traction. With ongoing improvements in waste reduction and resource management, 3D printing is not just about innovation but also about creating a more sustainable future. As businesses adapt to these changes, the landscape of manufacturing will continue to evolve, unlocking new opportunities and capabilities across various sectors. The future of 3D printing holds exciting possibilities that are worth watching closely.